Market prospects of new energy cables

New energy cables will be the development goal of our company's wires and cables. New energy cables can be generally divided into: photovoltaic cables, wind power generation cables, cables for offshore oil platforms, cables for nuclear power plants, electric vehicle cables, cables for inland conventional and unconventional natural gas development, etc. The following editor will introduce several main categories and performance of new energy cable products, domestic and international application standards, and development prospects.

Wind power cable Wind power, as a clean and renewable energy source, is currently the most large-scale, technologically mature, and commercially promising power generation model among many new energy sources. According to public information, the available wind energy resources in mainland China and its coastal areas have reached nearly 1 billion kW. According to China's "Renewable Energy Medium and Long Term Development Plan", the total installed capacity of wind power in China reached 30 million kW in 2020, and 2013-2020 is still a promising golden period. Wind power generation cables include control cables, signal cables, and twist resistant power cables in the wind turbine cabin and tower. Due to the harsh wind farm environment and the twisting of power cables with the swinging of the impeller, wind power generation cables generally require high requirements, such as low temperature resistance, oil resistance, torsion resistance, climate resistance, UV resistance, acid and alkali resistance. Currently, there is no national standard for wind power generation cables in China, Only industry standards such as TICW01-2009 "Twist resistant Flexible Wires for Wind Power Generation with Rated Voltages of 1.8/3kV and Below" issued by the National Wire and Cable Quality Supervision and Testing Center.

Tower cable is the most commonly used cable in wind power generation systems, and we often refer to wind power cables as such. Due to the continuous forward and backward swing of the tower cable with the wind turbine, the performance requirements of the tower cable are extremely strict, which not only ensure the structure is soft, but also require high tensile strength, low temperature resistance (-40 ℃), UV resistance, torsion resistance, salt spray resistance (such requirements exist in offshore wind power plants), seawater corrosion resistance, friction resistance, climate aging resistance, flame retardancy, and other properties.

The development of photovoltaic cable solar energy has shown a spray well development in recent years. As of the end of 2010, China's installed capacity of solar photovoltaic power generation has reached 893 MW, ranking 7th in the world. It is expected that by 2020, the total installed capacity of solar photovoltaic power generation in China will exceed 30000 MW. The country also provides support for photovoltaic construction projects. Photovoltaic power generation has driven the rapid development of related products, such as photovoltaic cables. Usually, the low-voltage direct current generated by photovoltaic power generation needs to be converted into alternating current, and the connecting cable between photovoltaic cells and AC/DC inverters is the photovoltaic cable. In theory, a photovoltaic module typically requires 2 0 The single core cable between 8 and 1, so if we follow the corresponding development speed of photovoltaic modules, the usage of photovoltaic cables in China will reach about 150000 km by 2020, with a large demand space. The abbreviation for photovoltaic cable is PV cable, which has a relatively simple structure, including conductor, insulation, and sheath.

At present, there is no national standard for photovoltaic cables in China. The most authoritative certification for photovoltaic cables internationally is TUV Rheinland TUVMARK and UL certification, mainly referring to standard 2 Pfg 1169 or UL 4703, and the samples need to be sent to Germany or the United States. Therefore, the certification cycle is long, the cost is high, and the design focus of various products is different.

新能源电缆的市场前景

新能源电缆将是我公司电线电缆的发展目标。新能源类电缆大体可分为:光伏电缆、风力发电电缆、海洋石油平台用电缆、核电站用电缆、电动机车类电缆、内陆常规与非常规天然气开采用电缆等。下面小编将介绍几种主要的新能源电缆产品类别与性能、国内外应用标准、开发前景等。

风力发电电缆风能作为一种清洁的可再生能源,目前也是众多新能源中最具规模、技术最成熟、最有商业发展前景的发电模式。据公开资料显示,我国大陆及近海岸可利用风能资源已近10亿kW,我国《可再生能源中长期发展规划》中指出,2020年我国风电总装机容量达到3000万kW,2013-2020年仍是大有可为的黄金时期。风力发电电缆有风电机舱和塔筒内的控制电缆、信号电缆、耐扭曲电力电缆等,因风场环境恶劣,且电力电缆随叶轮摆动而扭曲,所以风力发电用电缆一般要求较高,如要求耐低温、耐油、耐扭曲、耐气候、耐紫外线、耐酸碱等,我国目前风力发电电缆暂无国家标准,只有国家电线电缆质量监督检测中心颁发的TICW01-2009《额定电压1.8/3kV及以下风力发电用耐扭曲软电线》等行业内标准。

塔筒电缆是风力发电系统中应用最多的电缆,我们经常说的风电电缆就是指此类电缆。因为塔筒电缆随风机不断的正反向摆动,所以塔筒电缆性能要求极为严格,即要保证结构柔软,又要求具有较高的抗张强度、耐低温(-40℃)、耐紫外线、耐扭转、耐盐雾(近海风电厂有此类要求)、耐海水腐蚀、耐摩、耐气候老化、阻燃等性能。

光伏电缆太阳能的开发近年来呈现喷井式发展,截至2010 年末,我国太阳能光伏发电装机容量已经达到893 MW,位居世界第7。预计到2020年,我国的太阳能光伏发电装机总容量将超过30 000 MW。国家也在光伏建设项目上给予支持。光伏发电已带动相关产品,如光伏电缆的迅速发展。通常光伏发电产生的低压直流电需转换为交流电,光伏电池与交直流逆变器间的连接电缆就是光伏电缆。理论上讲一个光伏组件一般需要2根0. 8-1之间的单芯电缆,所以说如果按照相应光伏组件发展速度,到2020年我国光伏电缆的用量将达到15万km左右,需求空间较大。光伏电缆英文缩写是PV电缆,结构较为简单,即导体、绝缘、护套。

我国目前暂时没有光伏电缆国家标准,国际上光伏电缆最为权威的认证是TUV 莱茵TUVMARK与UL认证,主要参考标准2 Pfg 1169或UL 4703,且样品要送往德国或美国,所以认证周期较长,费用较高,且各样品设计侧重点不同。

Types of New Energy Cables

Types of New Energy Cables

Characteristics and types of wind power cables

Characteristics and types of wind power cables

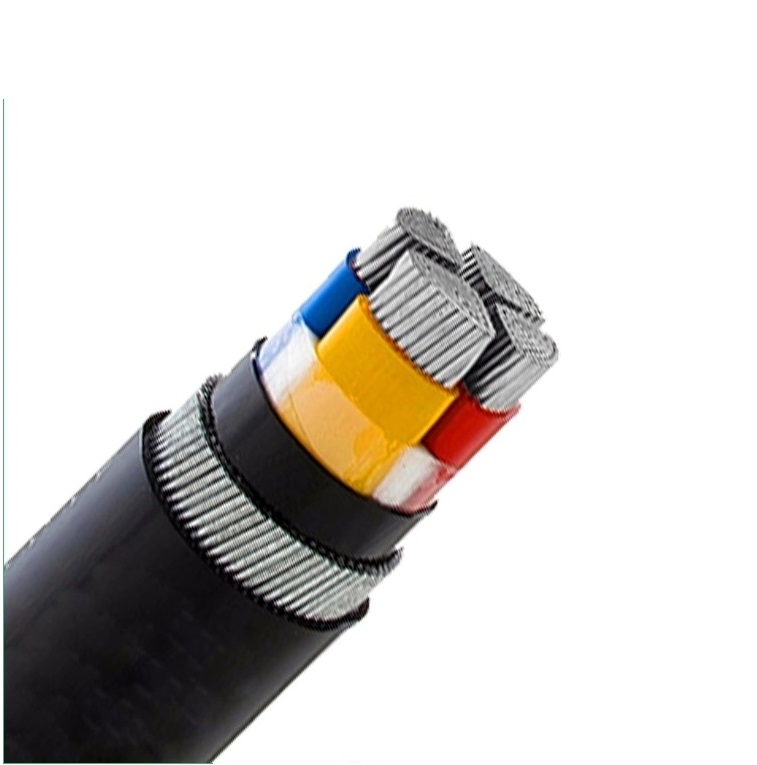

How to choose armored and unarmored cables?

How to choose armored and unarmored cables?